Elysator: Installation instructions

Installation

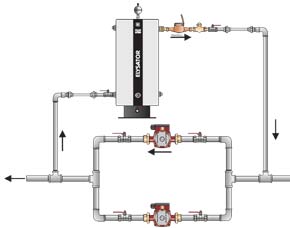

The Elysator should be installed in a by-pass, i.e. so a small volume of the total water volume will flow through. The Elysator does not have any electrical connection and does not use electricity. For some installations, (like boilers), a small circulating pump is necessary. The Elysator should be installed as close to the pump as possible, and at or below the lowest point in the system. The reason for this is that you want to collect as much particles as possible and to remove it from the system by the daily/weekly 10 to 30 second draining of the tank. Draining to be done with full flow through the tank. Always check that there is enough free height above the tank to pull the anodes for cleaning, (Type 15 to T260), and easy acces to the drain valve. On the larger units with manhole acces to the anodes there should be enough free space in front of the tank to open the manhole and to pull theAnodes from the tank.

The Elysator should be installed in a by-pass, i.e. so a small volume of the total water volume will flow through. The Elysator does not have any electrical connection and does not use electricity. For some installations, (like boilers), a small circulating pump is necessary. The Elysator should be installed as close to the pump as possible, and at or below the lowest point in the system. The reason for this is that you want to collect as much particles as possible and to remove it from the system by the daily/weekly 10 to 30 second draining of the tank. Draining to be done with full flow through the tank. Always check that there is enough free height above the tank to pull the anodes for cleaning, (Type 15 to T260), and easy acces to the drain valve. On the larger units with manhole acces to the anodes there should be enough free space in front of the tank to open the manhole and to pull theAnodes from the tank.

NB! galvanized pipes Installation not to be used in hot waterinstallations.

Boiler water treatment

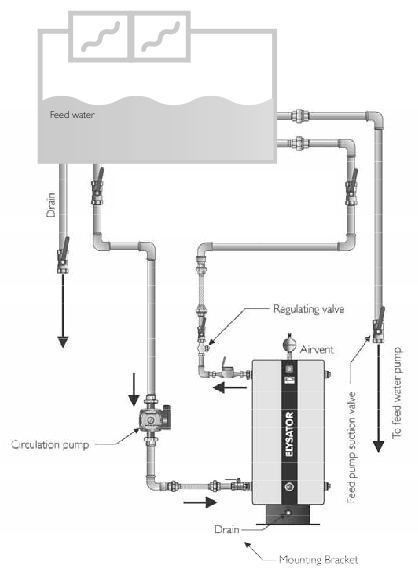

The Elysator should be located preferably as shown on the illustration (fig. 14-1). Both suction and discharge line to be joined in below the «low level» alarm in the hot well. A separate circulation pump to be mounted as low as possible (normally from drain valve). The water flow should be adjusted with the regulating Feed water valve after the water counter, while the ball valve on the inlet remains fully open. We underline the importance that the Elysator should be located as low as possible in above system (preferably deck below hot well) or use by meens of near the feed pump suction line goose neck for compensation of deck below. In order that no air pocket will be built up inside in the Elysator, avoid cavitation in the circulation pump and that the existing sludge in the system will enter more easily / faster into the Elysator. Some boiler plants might have been fitted with the anodes built-in in the hot well (feed w.tank). PS ! If it's not possible to install the Elysator below hotwell, there should be made a "goose neck" (above height of hot well) to avoid any air inside the Elysator. Note that the hot well temperature to be kept from 90 to 95oc. When boiler is idle the boiler should be topped up and if possible a circulation should be established between hot well and boiler(s). If the boiler is not under pressure then the Elysator circulating pump can be fitted with a recirculating line to the boiler filling line with a valve.

The Elysator should be located preferably as shown on the illustration (fig. 14-1). Both suction and discharge line to be joined in below the «low level» alarm in the hot well. A separate circulation pump to be mounted as low as possible (normally from drain valve). The water flow should be adjusted with the regulating Feed water valve after the water counter, while the ball valve on the inlet remains fully open. We underline the importance that the Elysator should be located as low as possible in above system (preferably deck below hot well) or use by meens of near the feed pump suction line goose neck for compensation of deck below. In order that no air pocket will be built up inside in the Elysator, avoid cavitation in the circulation pump and that the existing sludge in the system will enter more easily / faster into the Elysator. Some boiler plants might have been fitted with the anodes built-in in the hot well (feed w.tank). PS ! If it's not possible to install the Elysator below hotwell, there should be made a "goose neck" (above height of hot well) to avoid any air inside the Elysator. Note that the hot well temperature to be kept from 90 to 95oc. When boiler is idle the boiler should be topped up and if possible a circulation should be established between hot well and boiler(s). If the boiler is not under pressure then the Elysator circulating pump can be fitted with a recirculating line to the boiler filling line with a valve.

NB! galvanized pipes not to be used in hot water installations.